Best External Tooth Lock Washers for Heavy-Duty Applications

When you're working on projects that involve high-stress, vibration-prone environments, securing your fasteners properly is crucial. One of the most effective components for this job is the External Tooth Lock Washers . Designed to keep your fasteners tight and secure, these washers offer exceptional anti-loosening performance, especially in machinery, automotive systems, and structural frameworks.

In this post, we’ll explore why External Tooth Lock Washers are an essential component for your fastening needs. From corrosion resistance in harsh environments to providing the best grip in heavy-duty applications, we’ve got you covered. Let's dive into the details of these powerful washers and how they can enhance the durability of your projects.

Table of Contents:

- What is an External Tooth Lock Washer?

- Why Choose Stainless Steel External Tooth Washers?

- How Does an External Tooth Lock Washer Work?

- How to Choose the Right Square Washer for Your Project

- Applications of High-Strength External Tooth Lock Washers

- Why Opt for Premium Tooth Lock Washers?

- Choosing the Best External Tooth Lock Washer for Your Needs

What is an External Tooth Lock Washer?

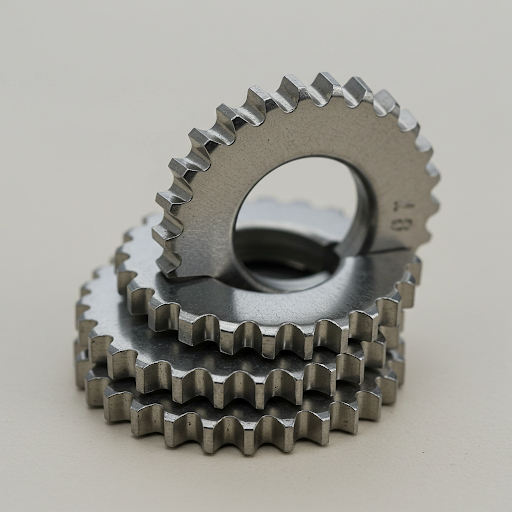

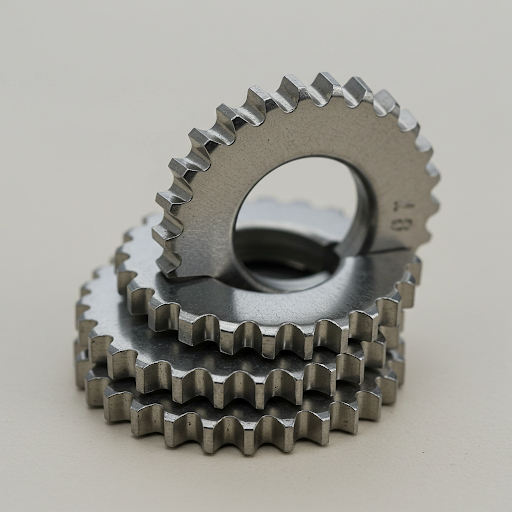

An External Tooth Lock Washers is a type of lock washer with serrated teeth on its outer circumference. These teeth are intentionally designed to bite into both the fastener and the surface material, creating a secure and stable connection. By applying this gripping force, external tooth lock washers prevent fasteners from loosening due to vibration, movement, or high torque. They are crucial for ensuring that the assembly remains intact in high-stress applications where other washers might fail.

Best External Tooth Lock Washer for Heavy-Duty Applications

When it comes to high-pressure, high-torque environments, the best external tooth lock washer for heavy-duty applications is one that combines durability with superior locking capabilities. These washers are designed to withstand the most demanding conditions, making them an essential component in industrial machinery, automotive, and structural applications.

Key Features of External Tooth Lock Washers:

- Serrated Teeth for Enhanced Grip: The serrated edges of the External Tooth Lock Washers provide a strong mechanical bond between the fastener and the material surface. This biting action ensures that the fastener stays securely in place even under vibration or constant movement. Unlike flat washers, external tooth lock washers excel at providing a stronger initial hold, making them ideal for applications with dynamic forces.

- Prevents Loosening Due to Vibration or Movement: In environments subject to vibration, shocks, or rotational forces—such as machinery or automotive parts—external tooth lock washers help keep fasteners from coming undone. By digging into the surface and creating friction, they provide resistance against the forces that typically lead to loosening and failure. The high-strength serrated lock washer for secure fastening helps ensure the integrity of your assembly even in the most challenging conditions.

- Ideal for High-Pressure Environments: Stainless steel external tooth lock washers are especially effective in high-pressure situations where conventional washers or nuts may not maintain their hold. The serrated teeth ensure that the fastener doesn’t back out, even when exposed to extreme forces like high torque or mechanical stress. This makes them an excellent choice for critical applications such as automotive, aerospace, machinery, and HVAC systems.

- Heavy-Duty Applications: From heavy machinery to structural projects, external tooth lock washers are indispensable in areas where stability and safety are non-negotiable. They help ensure that fasteners stay tight, preventing breakdowns or failures that could jeopardize the integrity of the entire assembly. Best External Tooth Lock Washers for heavy-duty applications are particularly suited for environments with high vibration, movement, and torque.

- Corrosion Resistance: Many stainless steel External Tooth Lock Washers are made from high-quality stainless steel or other corrosion-resistant materials, ensuring they perform well even in harsh environments. Whether exposed to moisture, chemicals, or extreme temperatures, these washers maintain their grip and integrity, preventing fastener loosening in both indoor and outdoor applications.

- Cost-Effective Solution: Compared to alternative locking mechanisms like nylon inserts or locknuts, external tooth lock washers are a simple, reliable, and cost-effective solution for keeping fasteners secure. They provide an efficient way to enhance safety without significantly increasing costs.

Why Choose Stainless Steel External Tooth Washers?

Stainless steel External Tooth Lock Washers are a reliable solution for fastener security in applications exposed to moisture, chemicals, and harsh environments. Their superior corrosion resistance makes them the go-to choice for industries like marine, food processing, and any environment prone to high humidity or exposure to corrosive substances. Stainless steel external tooth lock washers not only provide enhanced grip but also ensure long-lasting durability and performance in demanding conditions. If your project is exposed to elements like rain, chemicals, or moisture, investing in a stainless steel external tooth lock washer guarantees a secure, corrosion-resistant fastening solution.

Benefits of Stainless Steel Washers:

- Corrosion-resistant: Stainless steel offers excellent resistance to corrosion, making it ideal for applications in marine environments, chemical processing plants, and industries prone to rust or moisture exposure.

- Durable: stainless steel External Tooth Lock Washers are built to withstand repeated stress, vibration, and movement. Their durability ensures that fasteners stay securely in place even in high-stress conditions, preventing loosening over time.

- Rust-proof: Stainless steel washers are naturally rust-resistant, making them perfect for outdoor applications, heavy machinery, and other components exposed to the elements. This rust-proof quality guarantees the longevity of your fasteners in challenging environments.

- Safe for food-grade or medical equipment: Non-reactive and hygienic, stainless steel external tooth washers are perfect for food processing and medical equipment, where cleanliness and hygiene are paramount. They help maintain the integrity and safety of fasteners used in sensitive applications.

- Perfect for Harsh Conditions: Whether you're dealing with high humidity, chemical exposure, or extreme temperatures, stainless steel external tooth lock washers are your go-to choice for ensuring that fasteners remain secure and functional over the long term.

By choosing stainless steel external tooth washers, you are investing in a durable, corrosion-resistant, and rust-proof solution that stands the test of time. Whether for industrial, marine, or medical applications, these washers provide the performance you can rely on in the harshest conditions.

How Does an External Tooth Lock Washer Work?

An External Tooth Lock Washers functions by embedding its serrated teeth into the mating surfaces of the fastener and material, creating a strong frictional grip. This "biting" action increases friction and prevents the fastener from rotating or loosening, even in high-vibration environments. By providing added resistance, the washer ensures a secure connection that can withstand constant stress or movement.

Key Mechanisms:

- Increased friction between the washer and fastener: The serrated teeth on the outer edge of the washer bite into both the material and the fastener, increasing friction and preventing movement. This makes it highly effective in preventing loosening under torque or vibration.

- Prevents rotation or loosening under dynamic conditions: External Tooth Lock Washers are designed to resist rotation. This is crucial in dynamic environments, such as heavy machinery, automotive components, and other vibration-prone applications, where fasteners can easily become loose over time without this added security.

- Maintains tension and ensures secure connections in vibration-prone settings: The washer helps maintain the necessary tension between fastener components, keeping the connection secure. Whether used in automotive, machinery, or structural applications, the washer ensures that the fastener remains tightly in place, even under constant movement or stress.

Applications of High-Strength External Tooth Lock Washers

External Tooth Lock Washers are used across a variety of industries where securing fasteners against vibrations and movement is essential. These washers are crucial in ensuring the stability and safety of various mechanical systems.

Key Applications:

- Heavy machinery assemblies: Ensures fasteners remain secure under extreme vibration.

- Electrical equipment: Guarantees stable and secure electrical connections that can withstand thermal and mechanical stress.

- Automotive engines: Prevents loosening of bolts in vibration-heavy environments.

- HVAC systems: Keeps fasteners tight under repeated material expansion and contraction.

- Steel structures: Ensures fasteners remain secure under extreme vibration.

- Railway and wind turbine equipment: Ideal for applications subjected to constant movement or forces.

Why Opt for Premium Tooth Lock Washers?

Not all lock washers are created equal. Opting for a high-strength serrated External Tooth Lock Washers ensures that your fasteners remain secure and resistant to loosening, even under the toughest conditions. Premium washers made from stainless steel or high-strength alloys offer the durability and performance needed for heavy-duty applications.

Reasons to Choose Premium Washers:

- Better grip: Premium washers provide superior resistance against loosening.

- Longer lifespan: Made from durable materials, they last longer and reduce replacement costs.

- High load tolerance: Designed to handle extreme pressure and vibration without losing effectiveness.

- Enhanced safety: Keeps fasteners in place, preventing failure and ensuring overall system integrity.

Choosing the Best External Tooth Lock Washer for Your Needs

Selecting the best External Tooth Lock Washers involves understanding the specific demands of your application and matching them with the washer’s features. Whether you're working on a high-vibration assembly, structural component, or machinery installation, the right washer can significantly enhance performance and longevity.

Key Considerations:

- Material: For projects exposed to moisture, chemicals, or outdoor conditions, go with a stainless steel External Tooth Lock Washers for corrosion resistance. For heavy-duty mechanical applications, choose hardened steel for its superior tensile strength and reliability.

- Material: For projects exposed to moisture, chemicals, or outdoor conditions, go with a stainless steel External Tooth Lock Washers for corrosion resistance . For heavy-duty mechanical applications, choose hardened steel for its superior tensile strength and reliability.

- Outer Diameter: The washer’s outer diameter should match or slightly exceed the bolt or screw size to ensure an even distribution of pressure and secure fastening.

- Tooth Profile: Look for a high-strength serrated lock washer for secure fastening. The quality and sharpness of the teeth determine how effectively the washer grips the surface and resists loosening.

- Load Rating:: Ensure the washer is rated to handle the mechanical load, torque, and vibration levels present in your application. Overlooking this can compromise the fastening integrity.

- Certifications: Opt for washers that meet relevant industry standards like ISO, DIN, or ASTM to ensure consistency, safety, and performance./li>

By carefully evaluating these factors, you can confidently choose the best External Tooth Lock Washers for heavy-duty applications—ensuring lasting stability and performance in even the most demanding environments.

About Sachin Shim

Our range of shim washers includes machined washers , industrial washers , ogee washers , tab washers , conical washers , sealing washers , and more. Designed for various applications, they ensure precise alignment, secure fastening, and durability in industries like aerospace, automotive, construction, and manufacturing. Whether you need industrial washers for heavy machinery, sealing washers for fluid systems, or ogee, tab, and conical washers for specialized uses, our selection guarantees optimal performance.

Author

Meet Seema, our expert author in industrial materials with a deep understanding of

Bolts. With years of experience, Seema brings valuable insights and expertise to

this guide, making them a trusted source for all things related to Bolts. Join us as

we delve into the art of Bolts with Seema leading the way.

List Other similar blogs