If you've ever worked on a project where vibrations or movement were a concern, you’ve probably heard about External Tooth Lock Washers . But what exactly are they, and why should you care? Well, these little components pack a big punch when it comes to securing fasteners. They’ve got serrated teeth that bite into the surface and fastener, keeping everything tight and in place—especially in environments where things tend to shake or move. In this post, we’ll walk you through how external tooth lock washers work, why stainless steel versions are a game-changer, and how to pick the best one for your needs. Let’s dive in and see why these washers are essential for keeping your projects secure!.

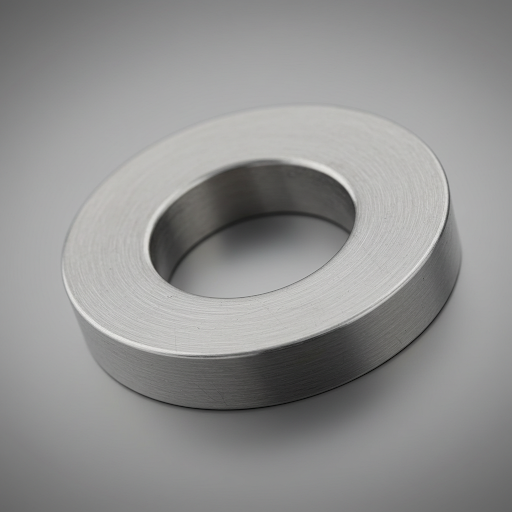

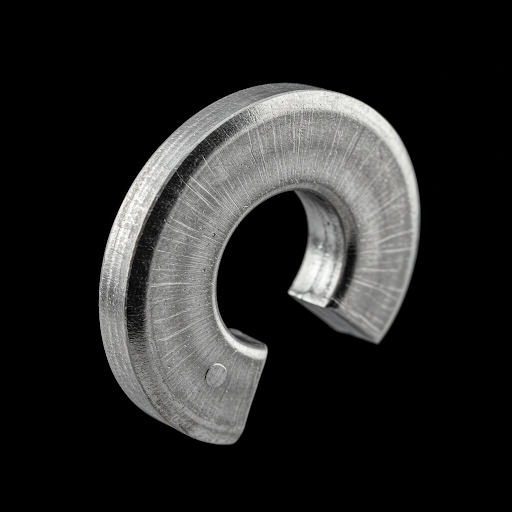

f you're dealing with vibration-prone assemblies or heavy-duty fastenings, chances are you’ve come across an External Tooth Lock Washers . But what exactly is it, and why is it so effective? An external tooth lock washer is a specially designed circular washer featuring teeth or serrations along its outer edge. These outward-pointing teeth are engineered to "bite" into both the surface material and the mating hardware (such as a nut or bolt head). This biting action increases friction and helps to prevent the fastener from loosening due to vibration, movement, or torque. Whether you're assembling automotive components, electrical systems, or machinery, external tooth lock washers play a crucial role in maintaining a tight and secure connection.

A stainless steel External Tooth Lock Washers isn’t just about adding grip to your fasteners—it’s about ensuring long-term reliability, especially in harsh or corrosive environments. Designed for performance in challenging conditions, a stainless steel external tooth lock washer combines the mechanical locking ability of external teeth with the superior corrosion resistance of stainless steel. This makes it a must-have for industries where exposure to moisture, chemicals, or outdoor elements is a given. Whether you're in construction, automotive, marine, or industrial equipment manufacturing, this type of washer provides that extra layer of protection and longevity.

Benefits of Stainless Steel:

Let’s keep it straightforward—an External Tooth Lock Washers works by using its sharp outer teeth to create a mechanical grip between the fastener and the surface material. When you tighten a bolt or nut over the washer, here’s what happens:

This makes an External Tooth Lock Washers perfect for any setup where you can’t afford loosening—think heavy machinery, bridges, railway equipment, or vibrating motors in industrial setups. It’s a small component with a big responsibility: locking everything down with confidence.

Whether you’re a contractor, a machine operator, or a DIY enthusiast, industrial External Tooth Lock Washers are indispensable in various heavy-duty and high-performance tasks. These washers are specifically designed to tackle applications where secure, vibration-resistant fastenings are critical. Let’s explore some of the common use cases where industrial tooth lock washers shine:

Common Use Cases:

When it comes to External Tooth Lock Washers , there’s a world of difference between ordinary washers and those designed for performance. High-quality tooth lock washers are engineered for maximum effectiveness and reliability, ensuring that your assemblies remain secure and durable even under the harshest conditions. Here’s why you should always insist on quality when selecting a tooth lock washer for your project:

Why You Should Insist on Quality:

Don’t settle for generic. Choose a high-strength serrated External Tooth Lock Washers for secure fastening—it may cost a bit more upfront, but the reliability and long-term performance it provides will pay off in the form of reduced downtime, maintenance costs, and the peace of mind that comes with knowing your assemblies are locked in tight.

When it comes to selecting the right External Tooth Lock Washers for your project, you’re not just choosing any washer — you’re choosing a crucial component that will ensure the stability and reliability of your entire fastening system. To make the right choice, here’s a quick checklist with key factors to consider:

Key Buying Factors:

The material of the washer plays a pivotal role in determining its performance in various environments.

Ensure that the outer diameter of the washer matches or slightly exceeds the size of the bolt you’re using. This ensures that the washer provides an adequate surface area for the external teeth to bite into, creating a strong locking action.

The external teeth of the washer are crucial for creating maximum friction and grip between the fastener and the material.

Look for washers with well-formed external teeth that can spread the load evenly over the surface. This creates a larger contact area, increasing the washer’s locking ability and preventing loosening under vibration.

Make sure the washer can handle the pressure and stress required by your application.

Each washer is designed for specific load ratings. For high-pressure environments, choose a washer with a higher load rating to ensure the fastener stays securely locked in place.

Check for certifications to ensure quality and reliability. Look for washers that meet international standards such as ISO, DIN, or ASTM to confirm that the product meets strict industry requirements and will perform as expected under demanding conditions.

Remember: You’re not just buying a washer — you’re securing your project’s future. A well-chosen External Tooth Lock Washers can prevent expensive breakdowns, safety hazards, and unnecessary downtime. By carefully considering these key factors, you’ll make the right selection to keep your assemblies tight and secure under any conditions. Choose wisely, and your project will be in safe hands!

From resisting vibration to ensuring structural integrity, the External Tooth Lock Washers is a silent hero in many industries. These small but powerful components play a crucial role in keeping fasteners secure, preventing loosening, and enhancing the reliability of machinery, construction projects, and even everyday consumer products. Whether you need an SS External Tooth Lock Washers for corrosion resistance in marine or chemical environments, or a heavy-duty industrial tooth lock washer for high-pressure machinery, choosing the right washer can make all the difference. A well-chosen tooth lock washer will boost the longevity of your assemblies, reduce maintenance costs, and help avoid safety risks caused by loosening fasteners.

Ready to upgrade your fasteners? Don't settle for just any lock washer — choose one that meets the demands of your specific application. Explore our high-quality collection of External Tooth Lock Washers designed for a range of industries and applications. Whether you need washers for heavy-duty machinery, automotive systems, or structural frameworks, we've got you covered with premium materials and reliable performance. Request a quote today for bulk requirements, or simply browse our selection to find the perfect fit for your next project.

Upgrade your fasteners now — ensure long-term security and peace of mind with high-quality tooth lock washers that never compromise on performance.

Our range of shim washers includes machined washers , industrial washers , ogee washers , tab washers , conical washers , sealing washers , and more. Designed for various applications, they ensure precise alignment, secure fastening, and durability in industries like aerospace, automotive, construction, and manufacturing. Whether you need industrial washers for heavy machinery, sealing washers for fluid systems, or ogee, tab, and conical washers for specialized uses, our selection guarantees optimal performance.