Innovations in Shim Manufacturing: Advancements Shaping the Industry

The humble shim, that thin sheet of material used for precise spacing and alignment, might seem like a simple component. But don't be fooled! The world of shim manufacturering is undergoing a fascinating transformation driven by groundbreaking advancements.

-

The Evolving Landscape of Shim Materials: Discover how new alloys and composites are pushing the boundaries of performance

-

Emerging Technologies: Uncover the exciting potential of materials like graphene and carbon nanotubes in shim production.

-

The Future of Shims: Get a glimpse of what lies ahead, including smart shims and automation advancements.

Whether you're an engineer, designer, or simply curious about the world of shim manufacturering , this article will shed light on the fascinating innovations shaping the future of shims.

The Evolving Landscape of Shim Materials

For decades, traditional materials like stainless steel and brass Shims Sheet have dominated the shim market. However, the demand for ever-increasing performance and functionality is driving the exploration of new and innovative materials. Here are some exciting developments:

- Polymer Composites: These lightweight and versatile materials like ss shims are finding their way into shim production. They offer advantages like electrical insulation, noise dampening, and resistance to chemicals.

- Advanced Alloys: New alloy compositions are being developed to offer superior strength, corrosion resistance, and thermal stability. Imagine shims that can withstand extreme temperatures without warping or losing their integrity!

- Exotic Metals:Materials like titanium and Hastelloy alloys are being explored for specialized applications where exceptional strength and resistance to harsh environments are crucial.

These advancements translate into stainless steel shims that are:

- More Durable: They can withstand harsher environments and heavier loads without compromising performance.

- More Versatile: A wider range of materials caters to diverse application needs, from high-temperature settings to corrosive environments.

- More Efficient: Lightweight materials can improve assembly efficiency and potentially reduce overall weight in your project.

Emerging Technologies

The world of materials science is constantly evolving, and the shim industry is taking notice. Here are some cutting-edge technologies that hold immense potential:

Graphene: This wonder material boasts exceptional strength, thermal conductivity, and electrical conductivity. Imagine ultra-thin shim sheet with incredible strength-to-weight ratios for high-precision applications.

Carbon Nanotubes: These microscopic tubes offer unparalleled strength and stiffness. Shims made with carbon nanotubes could revolutionize applications demanding extreme precision and minimal thermal expansion.

These emerging technologies could lead to:

Unprecedented Precision: ss shims with tolerances measured in microns, enabling even tighter fitz and improved performance.

Lightweight and Strong: Imagine shims that are incredibly strong yet virtually weightless, perfect for aerospace and other weight-critical applications.

On-Demand Manufacturing: The ability to 3D print shims at the point of need could revolutionize supply chains and maintenance processes.

The Future of Shims

As technology continues to evolve, we can expect even more exciting advancements in shim manufacturering . Here are some predictions for the future:

Smart Shims: Imagine stainless steel shims equipped with sensors that can monitor temperature, pressure, or even wear and tear. This data could be used for predictive maintenance and real-time performance optimization.

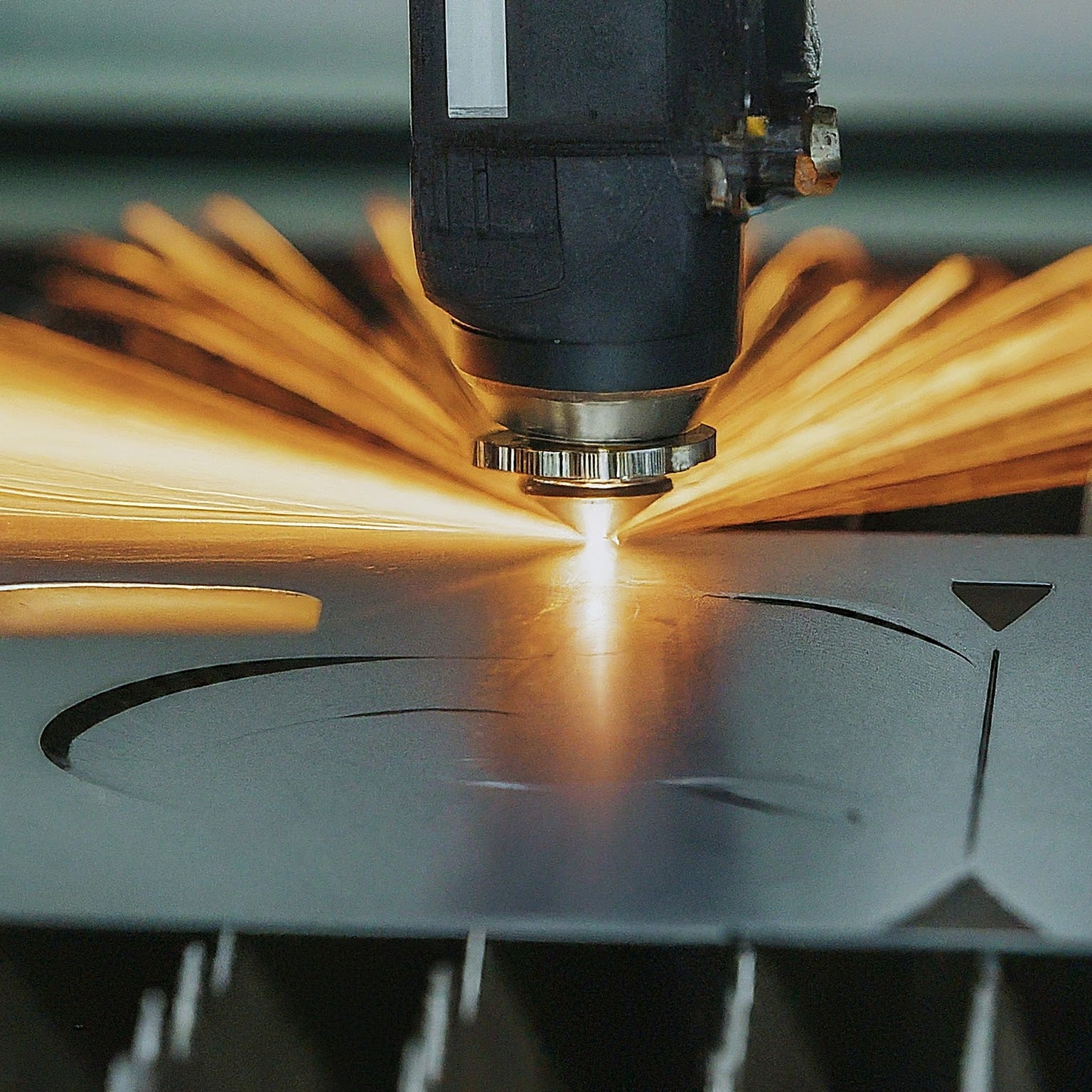

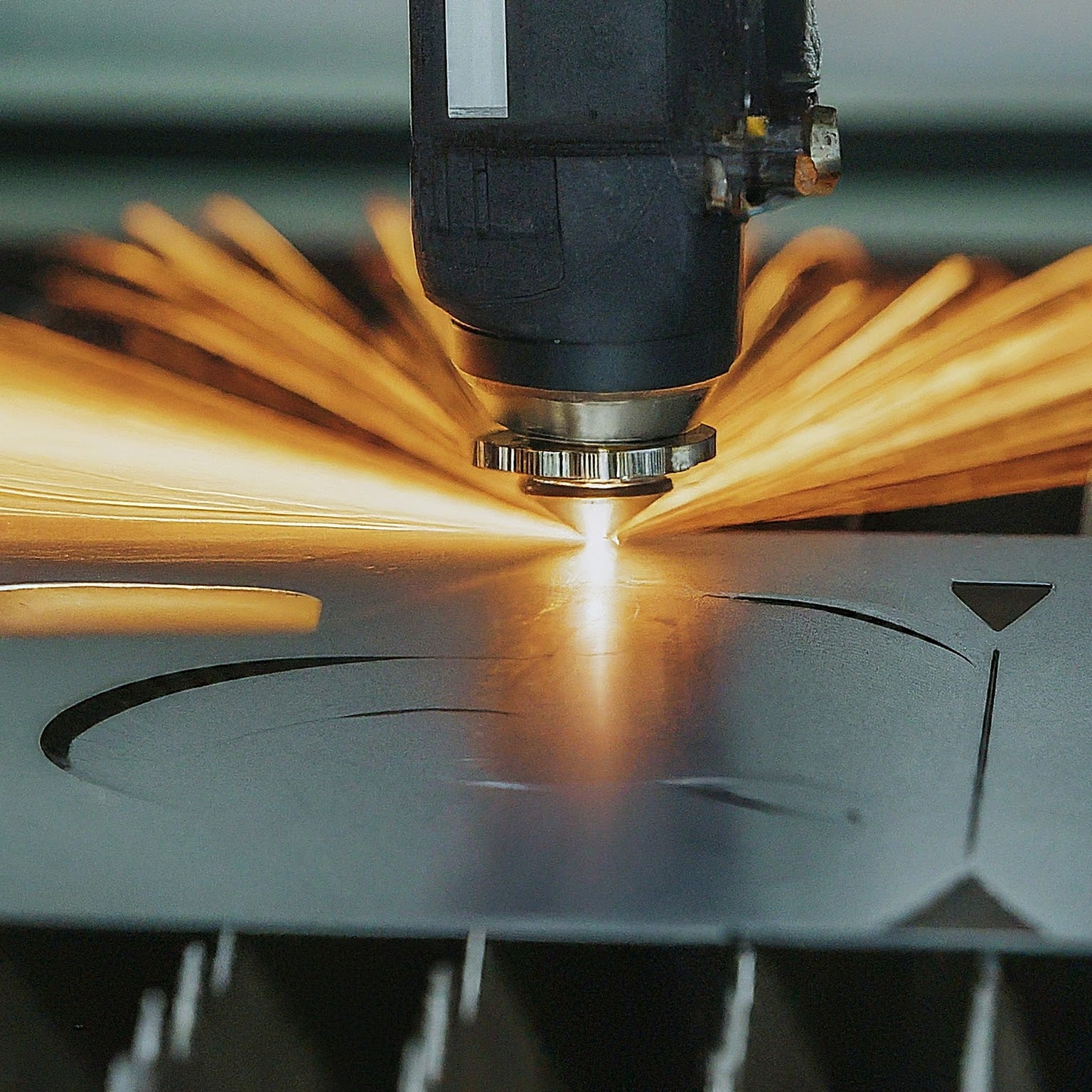

Increased Automation: The shim manufacturering shim manufacturing process could become even more automated, with robots handling tasks like material handling, laser cutting, and quality control. This would lead to increased efficiency and consistency in shim production.

Sustainable Practices: Sustainability is becoming a top priority across industries. We can expect to see the development of eco-friendly shim materials and more efficient manufacturing processes.

Conclusion

The future of shim manufacturering is brimming with exciting possibilities. New materials, innovative technologies, and a focus on sustainability are shaping a future where shims are even more versatile, durable, and efficient. As these advancements continue to unfold, the humble shim will undoubtedly play an even more critical role in various industries for years to come.

Author

Meet Seema, our expert author in industrial materials with a deep understanding of shim . With years of experience, Seema brings valuable insights and expertise to this guide, making him a trusted source for all things related to brass shim sheets. Join us as we delve into the art of crafting brass shim sheets with Seema leading the way.

List Other similar blogs