The humbleshim washer might seem like a simple component, but its role in countless machines and devices is anything but ordinary. These tiny spacers ensure precise alignment and optimal performance, and their manufacturing process is constantly evolving to meet the growing demands of modern industries.

In this blog post, we'll dive into the world of innovative shim manufacturing, exploring how advancements are shaping the industry and redefining what's possible:

For decades, the cornerstone of shim manufacturing relied on established techniques like:

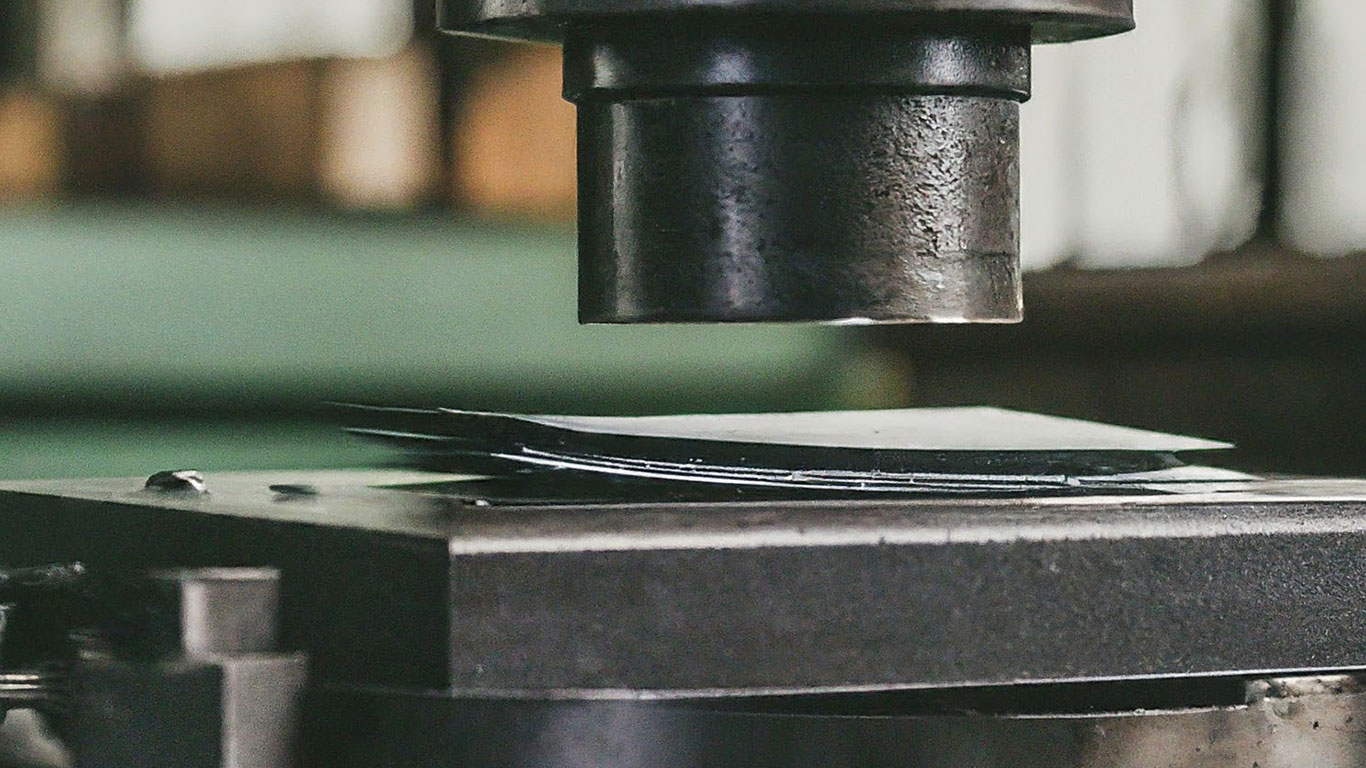

Utilizing specialized dies to precisely shape the washer from sheet metal.

Punching out individual washers from a larger sheet of material.

Creating a smooth and consistent surface finish.

While these traditional methods remain effective, the demand for higher precision, diverse materials, and customized solutions has spurred the development of innovative technologies.

The manufacturing landscape for shims is undergoing a transformation fueled by several groundbreaking advancements:

The exploration of new alloys and composite materials is resulting in shims with superior strength, corrosion resistance, and thermal stability. These advanced materials are especially crucial for applications in harsh environments or those requiring exceptional performance.

Research and development are also investigating the potential of lightweight, high-strength materials like graphene and carbon nanotubes. These materials offer the potential for ultra-thin, lightweight shims with exceptional durability.

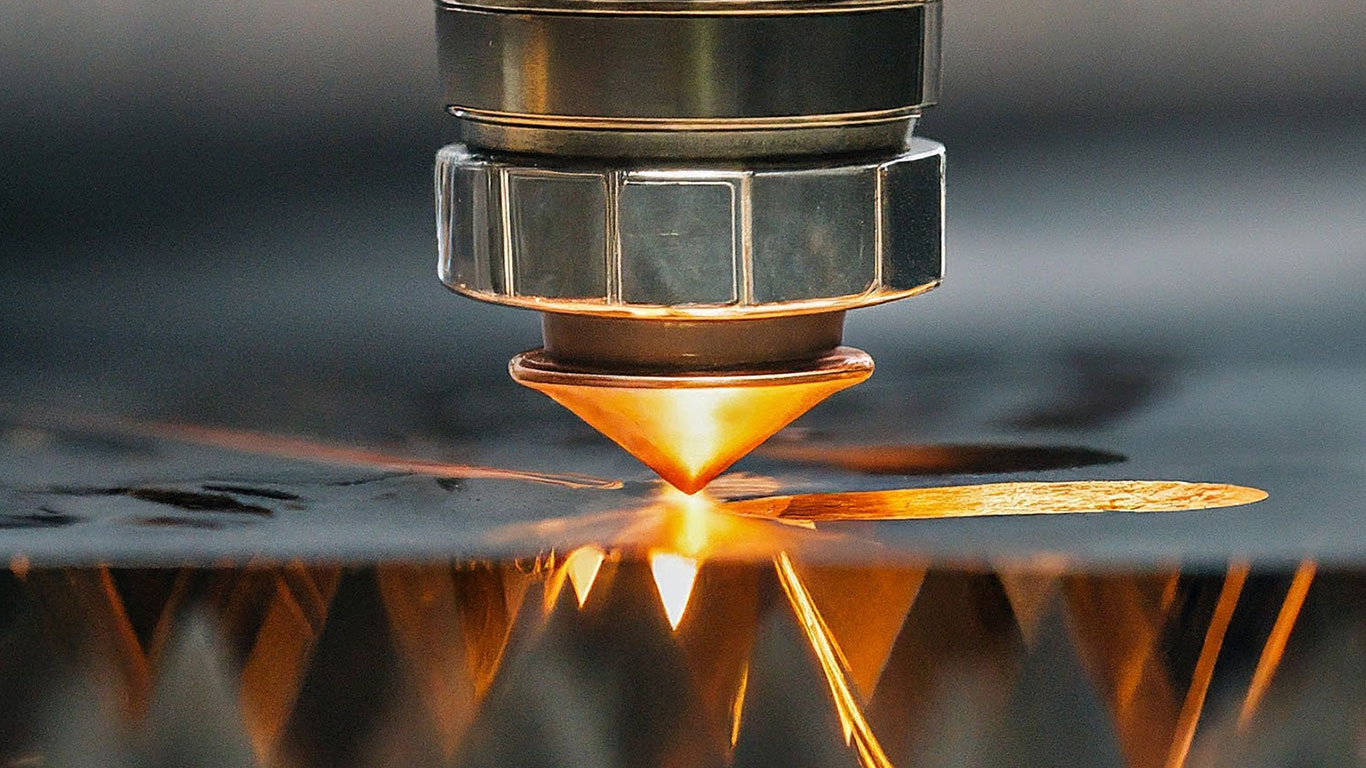

This technology offers unmatched precision and flexibility in creating shims with intricate shapes or complex geometries. This allows for the creation of highly customized shims for unique applications.

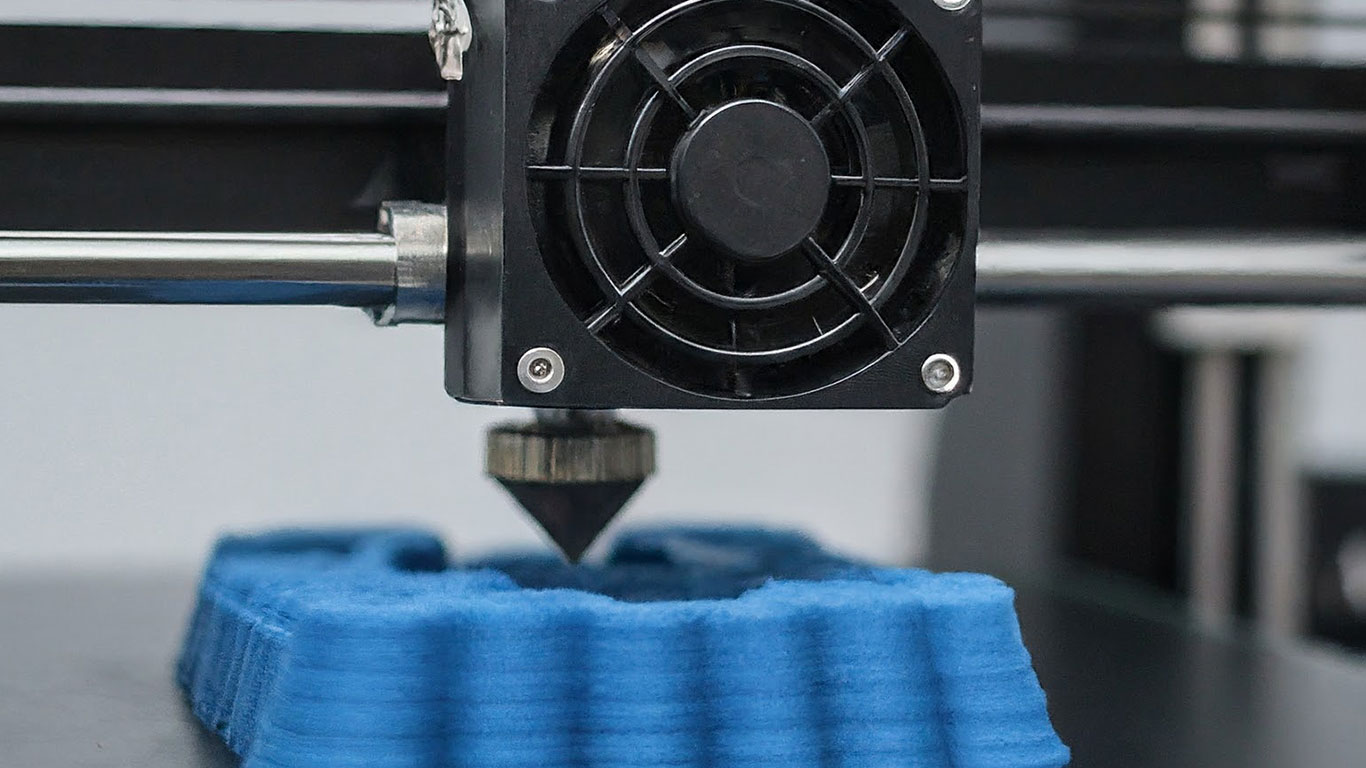

This revolutionary technology enables the creation of complex shim designs directly from digital models. This eliminates the need for traditional tooling and opens doors to on-demand manufacturing of customized shims.

The use of automated inspection systems equipped with sophisticated sensors and vision technologies ensures consistent and reliable quality control. This minimizes human error and guarantees every shim meets the highest standards.

With the growing demand for specialized applications, manufacturers are increasingly focusing on customization:

Applying various coatings or platings can enhance the shims' surface properties to optimize performance, improve wear resistance, or provide enhanced corrosion protection.

Leading manufacturers are actively engaging with customers to understand their specific needs and co-create customized shim solutions. This collaborative approach ensures the resulting shims perfectly meet the unique requirements of each project.

As technology continues to evolve, we can expect to see even more exciting advancements in shim manufacturing, including:

By staying informed about the latest innovations in shim manufacturing, you can make informed decisions and elevate your project to the next level. Seek partners who embrace cutting-edge technologies, high-quality materials, and a commitment to customization. With the right shim solution, you can ensure superior performance, optimal efficiency, and lasting success.

For further reading on stainless steel shims and related topics, check out these resources: