Stainless Steel Shim Plates: Key Insights for Machinery Maintenance

Maintaining machinery efficiently is crucial for the longevity and performance of equipment. Stainless steel shim plates play a significant role in this process by providing precision and stability. In this article, I'll guide you through everything you need to know about Stainless steel shim plates and how they can make a difference in your machinery maintenance routine.

Table of Contents:

- What Are Stainless Steel Shim Plates?

- Benefits of Using Stainless Steel Shim Plates

- Applications in Machinery Maintenance

- Choosing the Right Stainless Steel Shim Plate

- Installation and Handling Tips

- Common Issues and Solutions

- Conclusion

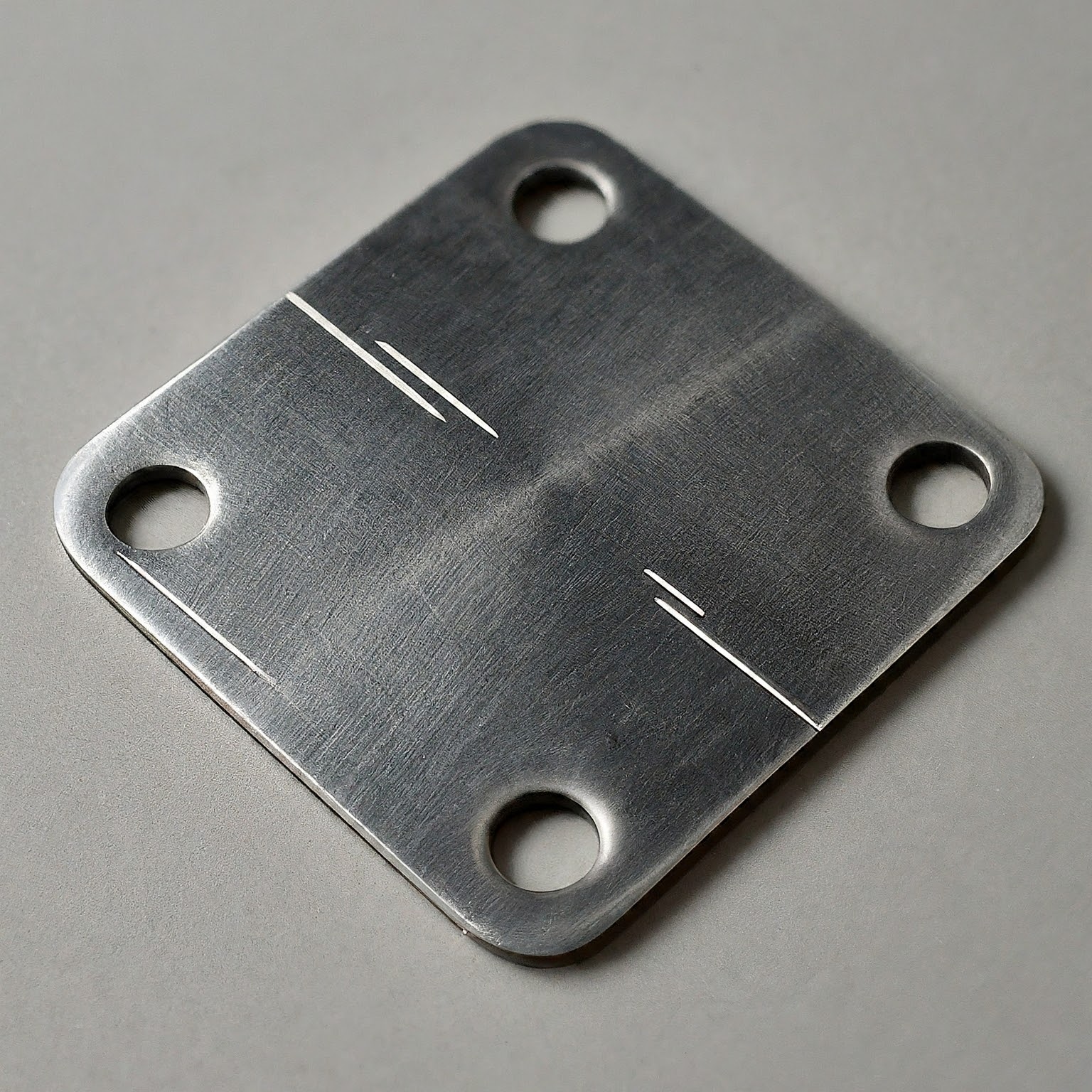

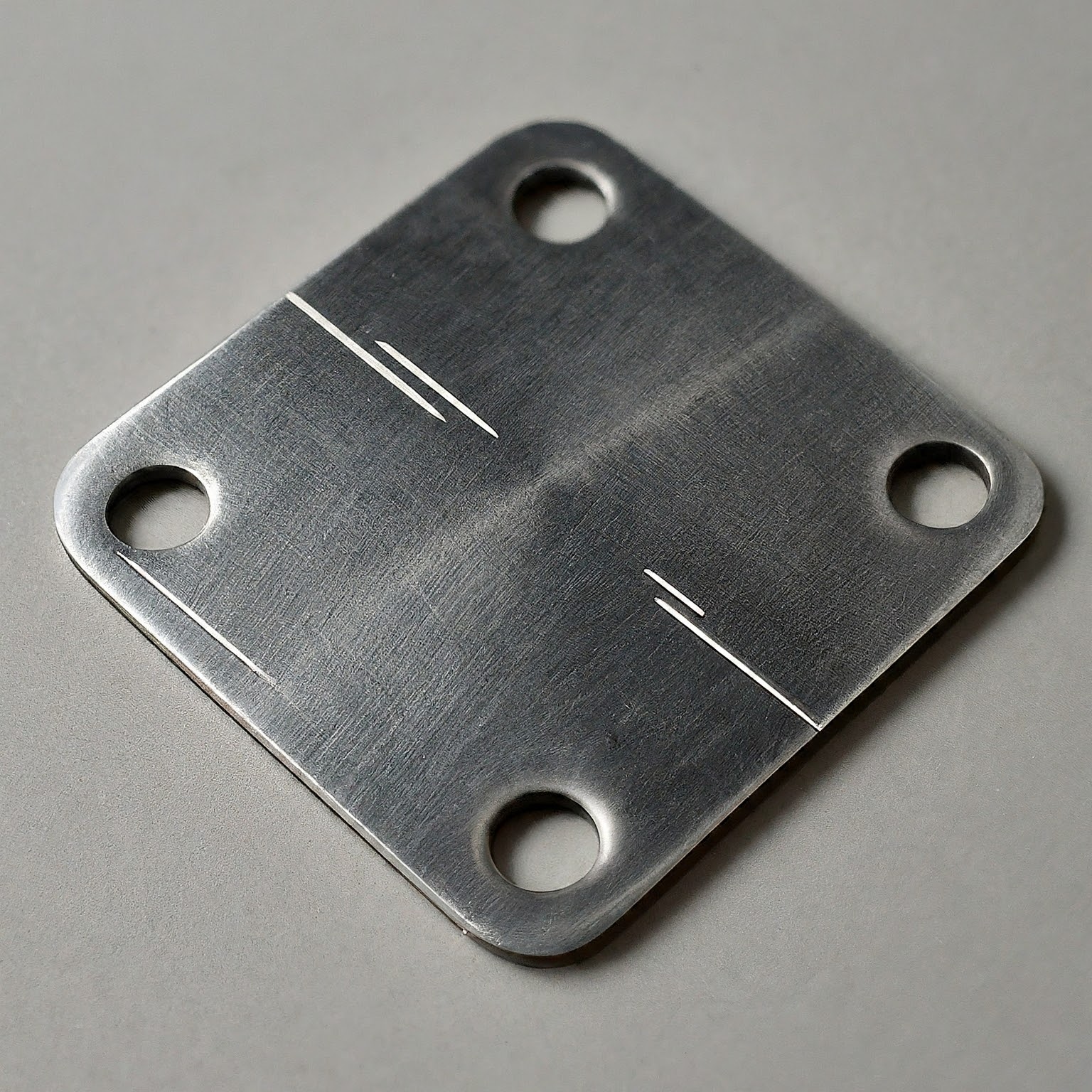

What Are Stainless Steel Shim Plates?

Stainless steel shim plates are thin, flat pieces of stainless steel used to fill gaps and provide precise adjustments in machinery and equipment. They are crucial for ensuring components fit together correctly and operate smoothly. Made from stainless steel, these shim plates offer excellent resistance to corrosion, heat, and wear, making them ideal for various industrial applications.

Key Characteristics:

Material: High-quality stainless steel.

Thickness: Typically very thin, from a few micrometers to a few millimeters.

Forms: Available in various shapes and sizes, including precut shims and custom options.

Benefits of Using Stainless Steel Shim Plates

Using stainless steel shim plates in your machinery maintenance routine comes with several advantages:

- Durability: Stainless steel's resistance to corrosion and wear extends the lifespan of the shim plates.

- Precision: They allow for precise adjustments, ensuring perfect alignment and performance of machinery components.

- Heat Resistance: Ideal for high-temperature environments, preventing deformation and maintaining stability.

- Versatility: Suitable for a wide range of applications, including machinery, automotive, and aerospace industries.

Applications in Machinery Maintenance

Stainless steel shim plates are versatile and find applications in various machinery maintenance tasks:

- Alignment Adjustments: Use shim plates to align components accurately, reducing vibrations and ensuring smooth operation.

- Gap Filling: Fill gaps between parts to improve the fit and prevent movement that can cause wear and tear.

- Height Adjustments: Adjust the height of components to achieve the desired position and functionality.

- Leveling: Ensure machinery and equipment are level for optimal performance and safety.

Examples of Use:

- Automotive Engines: In engines, ss shim plates help with precise adjustments for optimal performance.

- Industrial Equipment: Used to maintain alignment and prevent malfunctions in various industrial machines.

- Aerospace Components: Essential for ensuring the correct fit and function of critical aerospace components.

Choosing the Right Stainless Steel Shim Plate

Selecting the appropriate stainless steel shim plate for your needs is essential for achieving the best results. Here’s how to choose the right one:

- Determine the Required Thickness: Measure the gap or space you need to fill to choose the correct thickness.

- Select the Right Grade of Stainless Steel: Consider the operating environment and choose a grade that offers the necessary resistance to heat and corrosion.

- Consider Shape and Size: Choose from available shapes (rectangular, circular) and sizes based on your specific application.

- Check for Precision: Ensure the shim plates meet your requirements for precision and fit.

Installation and Handling Tips

Proper installation and handling of stainless steel shim plates are crucial for their effectiveness:

- Clean the Surface: Before installing the shim plates, ensure the surfaces are clean and free from debris.

- Use Proper Tools: Utilize the right tools for installation to avoid damaging the shim plates or surrounding components.

- Handle with Care: Avoid bending or deforming the shim plates. Handle them gently to maintain their shape and effectiveness.

- Verify Alignment: After installation, check the alignment and fit to ensure the shim plates are providing the desired adjustments.

Common Issues and Solutions

Here are some common issues with stainless steel shim plates and how to address them:

- Corrosion: Even though stainless steel is resistant to corrosion, exposure to harsh chemicals or environments may cause issues. Regularly inspect shim plates and replace them if necessary.

- Incorrect Thickness: If the shim plates are too thick or too thin, they may not provide the correct adjustment. Measure gaps carefully and select the appropriate thickness.

- Misalignment: Ensure proper installation and verify alignment after fitting the shim plates to prevent misalignment issues.

Conclusion

Stainless steel shim plates are essential components in machinery maintenance, offering durability, precision, and versatility. By understanding their benefits, applications, and proper handling techniques, you can ensure your machinery operates efficiently and reliably. Whether you’re dealing with alignment, gap filling, or height adjustments, stainless steel shim plates provide the stability and precision needed for optimal performance.

About Sachin Shim

Our range of shims includes metal, machine, industrial, precision, adjustable, machinery, engineering, custom, and alignment shims. These shims are designed for various applications, such as machinery alignment, fine adjustments in industrial-grade machines, engineering projects requiring steel shims, heavy-duty machinery requiring versatile metal shims, aerospace applications demanding precision stainless steel shims, automotive use requiring adjustable aluminum shims, precision engineering projects using high-quality brass shims, construction applications requiring durable plastic shims, specialized machinery needing customized shim solutions, and manufacturing processes requiring fine-tuning shims for precise alignment and accurate machine setup and leveling.

Author

Meet Sachin, our expert author in industrial materials with a deep understanding of brass shim sheets. With years of experience, Sachin brings valuable insights and expertise to this guide, making him a trusted source for all things related to brass shim sheets. Join us as we delve intothe art of crafting brass shim sheets with Sachin leading the way.

List Other similar blogs