Is the sound of dripping water driving you batty? Does a pesky leak under your sink have you reaching for a bucket every day? Don't call the plumber just yet! There might be a simple, affordable, and surprisingly effective solution lurking in your hardware store shim plates..

This blog post empowers you to become your own leak-stopping superhero. We'll delve into the world of shim plates, explore how they tackle plumbing leaks, and equip you with the knowledge to fix those drips and banish the blues.

Before we unleash the power of shim plates, let's identify the enemy: plumbing leaks. Often, these leaks stem from a common foe - settlements. Over time, buildings can settle slightly, causing misalignments in pipes and connections. This can lead to loose fittings, warped parts, and ultimately, those pesky drips

Here are some common culprits behind plumbing leaks:

Settlement can loosen the nuts that hold faucets in place, creating a pathway for leaks.

Settling pipes might no longer fit together snugly, leading to leaks at the connection points.

Similar to pipes, warped shutoff valves due to settlement can create leaks around the handle or base.

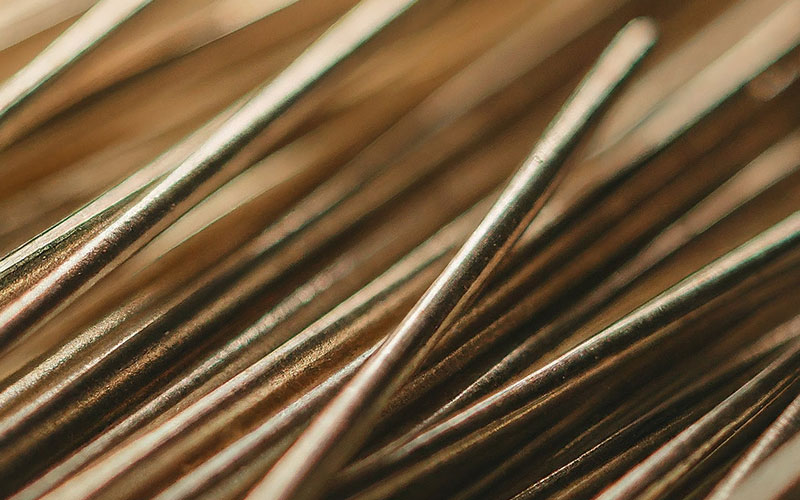

Shim plates are thin sheets of metal, typically stainless steel or brass, that come in various thicknesses.These unsung heroes act as warriors against leaks by:

Shim plates can be strategically placed behind loose faucets or warped valves, creating a level surface for a tighter fit. This eliminates gaps and prevents leaks.

Settlement can sometimes cause stress on certain parts of your plumbing system. Shim plates can add rigidity and support, minimizing movement and preventing leaks.

In some cases, slight misalignments in pipes might be causing leaks. A strategically placed shim plate can fill the gap and create a tighter connection, stopping the drip.

Now that you understand the power of shim plates, it's time to gather your tools and materials for battle:

Head to your local hardware store and choose shim plates made of stainless steel or brass. Select a thickness slightly thicker than the gap you're trying to fill.

This will help you tighten and loosen nuts on faucets and shutoff valves.

Useful for gripping and turning various plumbing components.

Handy for prying off decorative faucet handles or tightening screws.

Wrap this around threads on pipes and connections to create a watertight seal. (Optional, but recommended for added security).

Catch any drips while you work, and use the towel to clean up spills.

Before diving into repairs, it's crucial to prepare the leak site:

Locate the shut-off valve for the specific fixture you're repairing and turn it off completely. Open the faucet to release any remaining water pressure.

Remove any drawers or cabinets under the sink to provide ample workspace.

Identify the exact location of the leak. Is it coming from the faucet base, the handle, or the connection point between pipes?s

Here's a step-by-step guide to using shim plates for different types of plumbing leaks:

Cut a small piece of shim plate and place it strategically behind the base of the valve to create a level surface.

You've done it! With the power of shim plates and a little know-how, you've successfully banished that pesky leak. Take a moment to celebrate your DIY victory and enjoy the sweet sound of silence (no more dripping!).

Here are some tips to help prevent future leaks:

Get in the habit of checking your plumbing system for signs of leaks, loose connections, or any visible damage.

Every few months, give your faucet nuts a gentle twist to ensure they remain snug.

Don't ignore small drips or leaks. Fixing them early on can prevent a bigger mess and potential water damage down the road.

Don't let plumbing leaks turn your home into a dripping disaster. With a little knowledge, the right tools, and the power of shim plates, you can become your own leak-stopping superhero! So, head to your hardware store, gather your tools, and unleash your inner DIY warrior. Remember, a small shim plate can go a long way in keeping your home dry and leak-free!

Further read

Our range of shims includes metal, machine, industrial, precision, adjustable, machinery, engineering, custom, and alignment shims. These shims are designed for various applications, such as machinery alignment, fine adjustments in industrial-grade machines, engineering projects requiring steel shims, heavy-duty machinery requiring versatile metal shims, aerospace applications demanding precision stainless steel shims, automotive use requiring adjustable aluminum shims, precision engineering projects using high-quality brass shims, construction applications requiring durable plastic shims, specialized machinery needing customized shim solutions, and manufacturing processes requiring fine-tuning shims for precise alignment and accurate machine setup and leveling.