Washers That Prevent Bimetallic Corrosion: Best Solutions

Bimetallic corrosion, a silent destroyer, occurs when two dissimilar metals come into contact in the presence of an electrolyte. This electrochemical reaction can lead to significant damage to your structures or equipment. Fortunately, the right type of washer can act as a protective barrier. Let's explore different types of washers and discover how they can safeguard your metal components from this insidious threat.

Table of Contents

-

Understanding Bimetallic Corrosion

-

The Role of Washers in Corrosion Prevention

-

Types of Washers That Prevent Bimetallic Corrosion

-

How to Choose the Right Washer for Bimetallic Corrosion

-

Tips for Proper Installation and Maintenance

-

Additional Corrosion Prevention Tips

-

Conclusion

Understanding Bimetallic Corrosion

Bimetallic corrosion, also known as galvanic corrosion, occurs when two different metals come into contact with each other in the presence of an electrolyte, such as water. This type of corrosion can lead to significant damage, resulting in the premature failure of components.

If you’re looking for ways to prevent this issue, the right choice of washers is essential. In this guide, I’ll help you explore effective solutions to tackle bimetallic corrosion, focusing on the role of various washers like bimetallic-washers, shim washer manufacturers and many more.

The Role of Washers in Corrosion Prevention

Washers are often overlooked, but they play a crucial role in preventing bimetallic corrosion. By strategically placing a washer between two dissimilar metals, you can create a barrier that inhibits the electrochemical reaction. This simple yet effective solution can save you from significant headaches down the line.

Types of Washers That Prevent Bimetallic Corrosion

Choosing the correct washer is crucial for preventing bimetallic corrosion. Here are some options that can help:

- Plastic Washers: Made from materials like nylon or PTFE, plastic washers act as an insulating barrier between different metals, preventing direct contact and reducing the risk of corrosion. They are perfect for applications where metal contact should be avoided altogether.

- Rubber Washers: Rubber washers offer similar insulation as plastic ones, along with added flexibility and cushioning. They are effective in absorbing vibrations and preventing metal-to-metal contact.

- Non-Metallic Washers: Washers made from materials like composite polymers or elastomers provide excellent corrosion resistance and are often used in environments with chemical exposure. These include options from shim washer manufacturers specializing in non-metallic solutions.

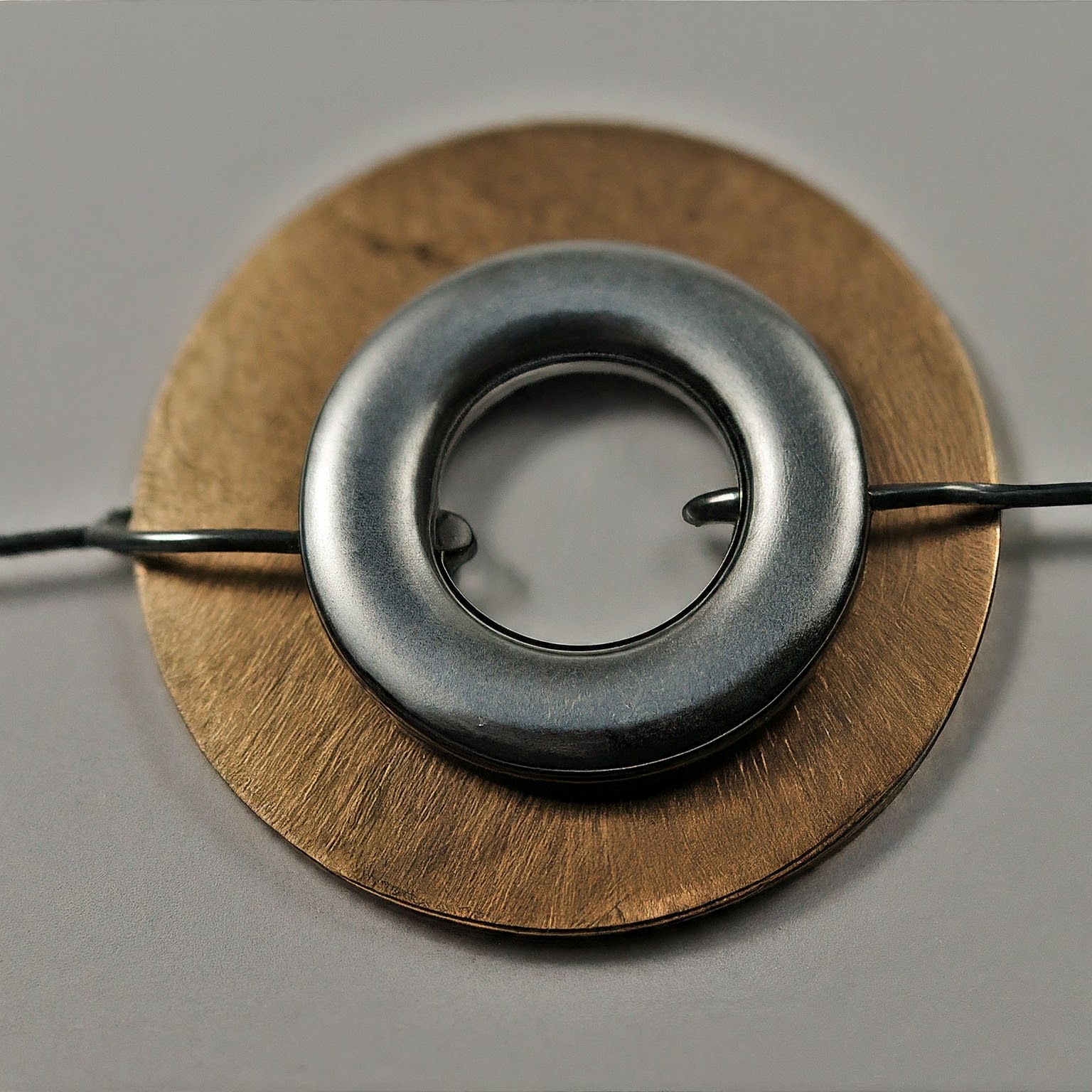

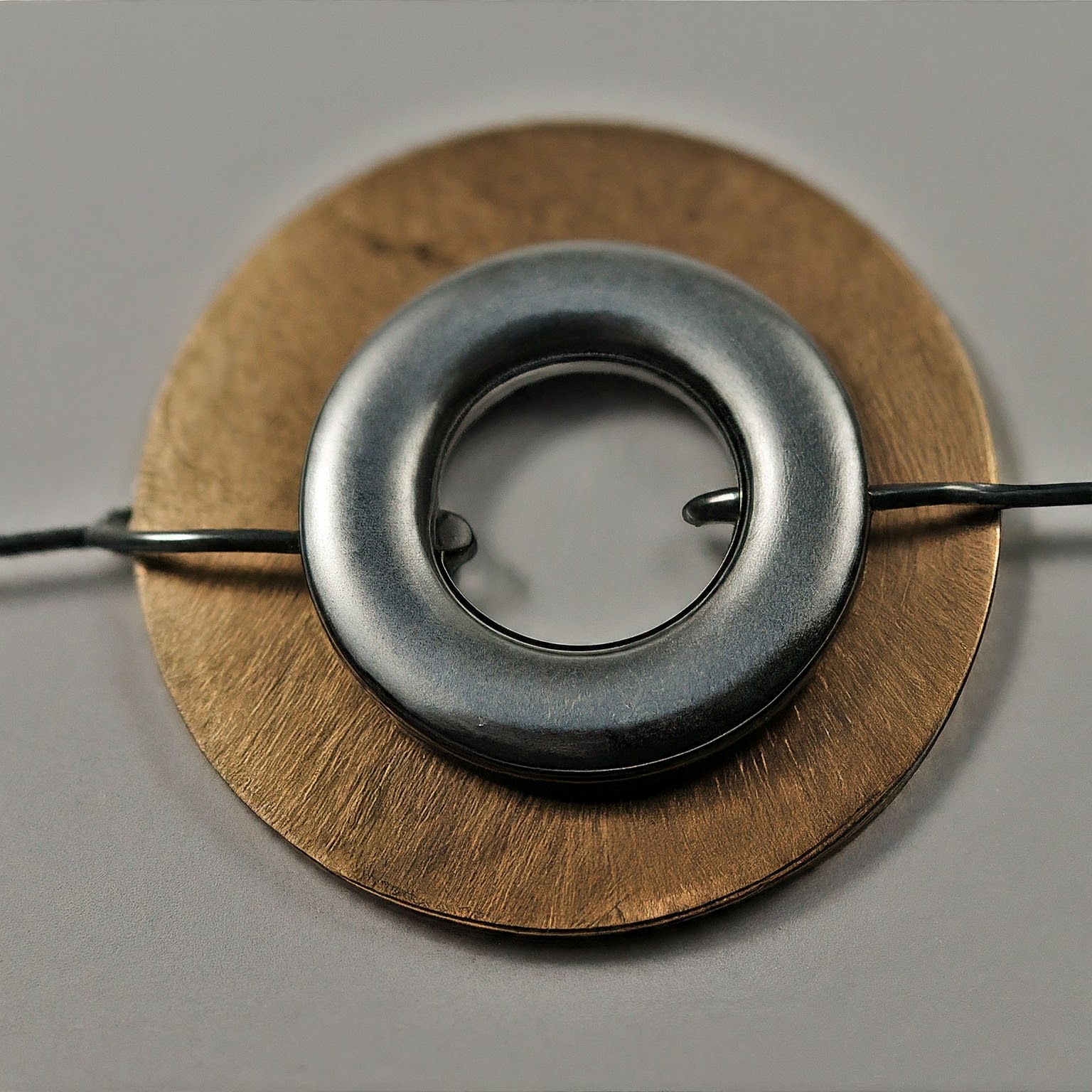

- Corrosion-Resistant Metal Washers: shim washer and bimetallic-washers are designed to resist corrosion. Stainless steel manufacturers are effective against rust and degradation, while bimetallic-washers handle the challenges of different metals in contact.

- Coated Washers: Washers with protective coatings, such as zinc or cadmium plating, help shield against corrosion. The coating acts as a barrier, reducing the potential for galvanic reactions between metals.

How to Choose the Right Washer for Bimetallic Corrosion

To effectively manage bimetallic corrosion, consider the following factors when selecting a washer:

- Material Compatibility: Choose a washer material compatible with the metals in your application. For example, if you’re working with stainless steel shim washer and aluminum, plastic washers or rubber washers might be the best choice to prevent corrosion.

- Environment: Consider the environment where the washer will be used. In harsh chemicals or extreme temperatures, opt for non-metallic washers or those with protective coatings. Consult with shim manufacturers for specific recommendations.

- Load and Pressure: Ensure the washer can handle the mechanical load and pressure of your application. Corrosion-resistant metal washers, such as those provided by SS Shim manufacturers, are often selected for high-load applications due to their strength and durability.

- Cost: Balance cost and effectiveness. Sometimes, using a combination of plastic washers for insulation and coated washers for additional protection may offer the most cost-effective solution.

Tips for Proper Installation and Maintenance

To ensure your washers like bimetallic-washers,stainless steel shim washer , plastic washer, etc effectively prevent bimetallic corrosion, follow these tips:

- Clean Surfaces: Ensure that surfaces where you apply washers are clean and free of debris. Dirt and contaminants can impact washer performance and increase corrosion risk.

- Apply Anti-Corrosion Coatings: For metal washers, applying an anti-corrosion coating can provide extra protection. This is crucial in environments prone to moisture or chemicals.

- Regular Inspections: Periodically inspect washers for signs of wear or damage. Replace them as needed to maintain optimal protection against corrosion.

- Proper Installation: Ensure washers are installed correctly, with appropriate pressure and alignment. Incorrect installation can compromise their effectiveness in preventing corrosion.

- Avoid Mixing Metals: Avoid using washers made of different metals in the same application when possible. If you must use different metals, ensure compatibility and consider Shim washers , plastic washers or rubber washers to isolate them.

Additional Corrosion Prevention Tips

- Coatings: Apply protective coatings to metal surfaces to create a barrier against corrosion.

- Regular Inspection: Check for signs of corrosion regularly and address issues promptly.

- Design Considerations: When designing structures or equipment, consider material compatibility and potential corrosion risks.

By incorporating these practices alongside the use of appropriate washers, you can significantly enhance the durability and lifespan of your metal components.

Conclusion

By understanding the principles of bimetallic corrosion and utilizing the right washers, you can significantly reduce the risk of damage to your metal components. It's a small investment that can yield substantial returns in terms of equipment longevity and maintenance costs. Bimetallic-washers are a valuable tool in your corrosion prevention arsenal. By choosing the right washers—whether they are plastic washers, rubber washers, stainless steel shim washer , or coated washers—you can effectively reduce the risk of galvanic corrosion.

Author

Meet Sachin, our expert author in industrial materials with a deep understanding of brass shim sheets. With years of experience, Sachin brings valuable insights and expertise to this guide, making him a trusted source for all things related to brass shim sheets. Join us as we delve intothe art of crafting brass shim sheets with Sachin leading the way.

List Other similar blogs