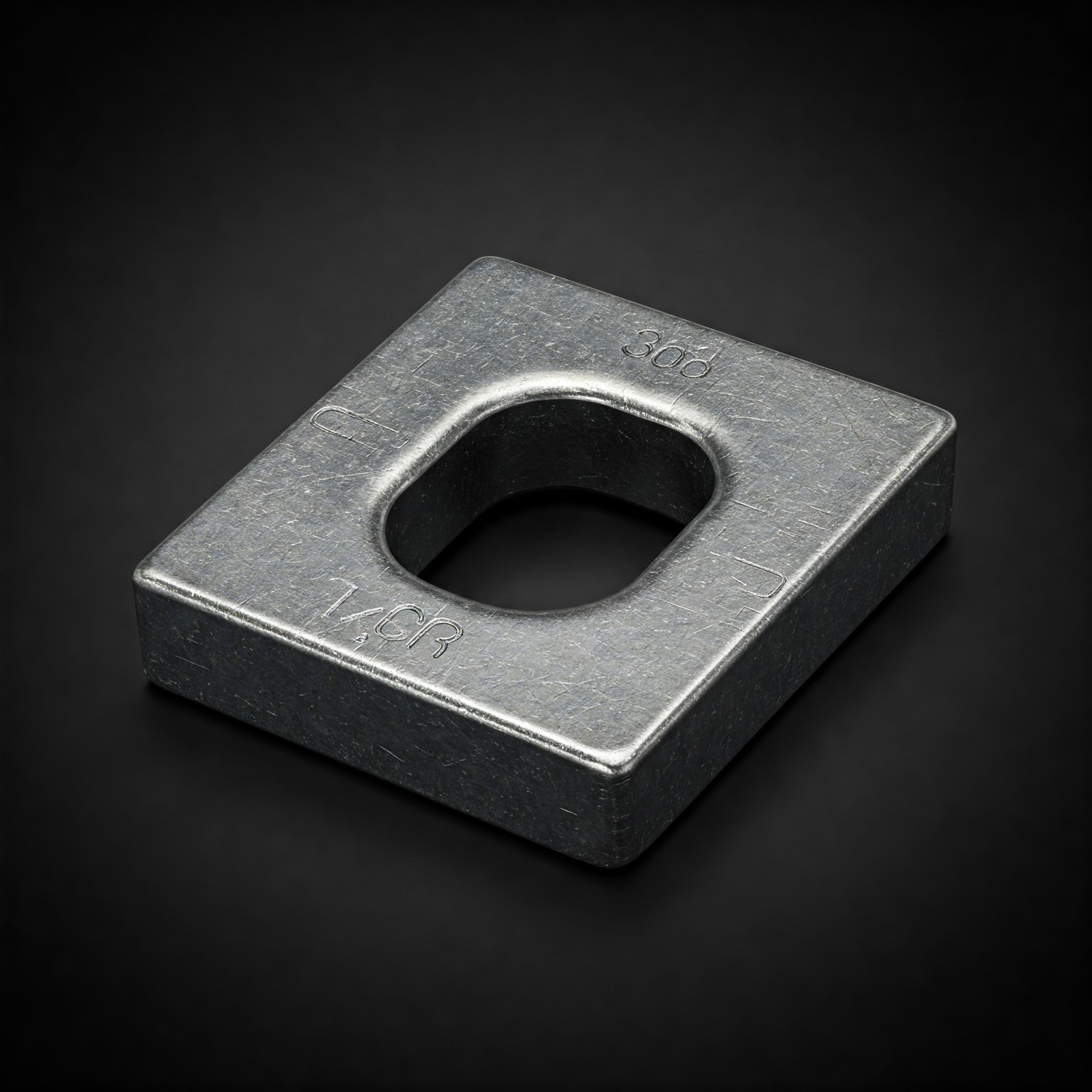

When it comes to securing critical components in construction or industrial setups, Square washer are a silent hero. Their simple geometry plays a crucial role in load distribution, fastening strength, and overall structural integrity. Whether you’re working with steel beams, timber frameworks, or high-vibration machinery, the right square washer can make all the difference between long-term reliability and premature failure.

In this guide, we’ll break down why square washers matter, explore different types, and help you choose the best square washer for structural applications—especially if you're looking to buy galvanized Square washer online or need custom square washers in stainless steel and mild steel.

Square washers stand out in demanding fastening applications because of their unique geometry and functionality. Unlike standard round washers, their square shape offers more surface coverage, stronger edge support, and greater resistance to movement—making them ideal for high-stress environments.

Here’s why Square washer are a go-to choice in many industries:

Square washer are commonly used with U-bolts, foundation bolts, and structural connections, where reliable support and long-term fastening strength are essential.

For projects that require high-strength square washers with corrosion resistance, especially in marine, construction, or industrial environments, choosing the right material—like stainless steel or hot-dip galvanized steel—can greatly enhance durability and performance.

Looking for premium Square washer tailored for your industrial needs ? Sachin Shim offers custom sizes, bulk availability, and pan-India delivery—ensuring your assemblies remain tough, tight, and trustworthy.

While round washers are standard for many general applications, Square washer bring unique advantages to the table—especially in environments where strength, stability, and alignment are critical.

Here’s a closer look at why square washers often outperform their round counterparts:

Thanks to these benefits, square washers are a top choice for:

When performance and reliability matter, Sachin Shim offers custom-manufactured square washers in various materials like stainless steel, hot-dip galvanized steel, and carbon steel—tailored to meet your project's specific needs.

Each project has unique demands. That’s why we at Sachin Shim offer a full range of washers to fit your exact use case:

Heavy-Duty Stainless Steel Square washer for Industrial Use

Made from 304/316-grade stainless steel, these washers offer excellent resistance to corrosion and wear. They're ideal for:

Galvanized Square Washers for Outdoor Construction

Our galvanized Square washer are zinc-coated for rust resistance. These are a go-to for builders looking to buy galvanized square washers online for:

Custom Square Washers in Stainless Steel and Mild Steel

Need something tailored? We manufacture custom square washers in a variety of dimensions and finishes. Perfect for:

Thick Square Washers for Heavy Load-Bearing Projects

For applications with high compression or tensile forces, go for thick square washers. These are designed to:

Precision-Machined Square washer for Engineering Applications

Manufactured with tight tolerances, these are ideal for:

Looking for dimensional accuracy and top-grade performance? Our precision-machined square washers for engineering applications deliver exactly that.

Square washer are trusted across industries where superior support, stability, and safety are non-negotiable. Thanks to their larger surface area and anti-rotation benefits, they’re a go-to solution in both structural and heavy-duty fastening systems.

Here are the most common applications where high-strength square washers are essential:

At Sachin Shim, we supply custom square washers built to perform under real-world stresses—available in stainless steel, galvanized, and carbon steel options with bulk quantities and pan-India shipping.

Choosing the right Square washer ensures long-lasting performance and structural integrity. Here’s a quick checklist to help guide your selection:

Whether you need Square washer for construction, marine environments, or heavy-duty equipment, Sachin Shim has the experience, inventory, and precision manufacturing to match your needs.

At Sachin Shim, we combine decades of expertise with precision manufacturing. Whether you're ordering standard sizes or need a custom-engineered solution, you’ll get:

Plus, with our easy online ordering process, you can now buy galvanized square washers online in just a few clicks.

Square washer might look like a small component—but they take on some of the biggest responsibilities in any fastening system. From bearing heavy structural loads in bridges and buildings to resisting corrosion in harsh marine environments, these rugged washers are built to perform where it counts.

Whether you're searching for a high-strength square plate washer for construction, a corrosion-resistant square washer for marine use, or a custom-fabricated washer tailored to your exact needs—we’re here to help.

Ready to order?

Browse our complete collection of industrial-grade square washers at SachinShim or contact our team for expert guidance and fast quotes. Let’s build something durable—together.

Our range of shim washers includes machined washers , industrial washers , ogee washers , tab washers , conical washers , sealing washers , and more. Designed for various applications, they ensure precise alignment, secure fastening, and durability in industries like aerospace, automotive, construction, and manufacturing. Whether you need industrial washers for heavy machinery, sealing washers for fluid systems, or ogee, tab, and conical washers for specialized uses, our selection guarantees optimal performance.